Salt-Free Water Conditioner with Scale Prevention | 12 GPM | Catalytic Carbon Whole House Up-flow Filtration System

- $1,195.00

$1,295.00- $1,195.00

- Unit price

- per

Couldn't load pickup availability

Built And Shipped Within 5 - 7 Bussiness Days

Salt-Free Water Conditioner with Scale Prevention | 12 GPM | Catalytic Carbon Whole House Up-flow Filtration System

Whole House Salt-Free Water Conditioning

Protect your home from scale while keeping essential minerals in your water. This 12 GPM system combines Template Assisted Crystallization (TAC) for scale prevention and an up-flow catalytic carbon filter for improved water quality.

Benefits:

-

Prevents lime scale on pipes, fixtures, and appliances; can reduce existing scale

-

Easy two-connection installation (pipe in/pipe out)

-

No backwash, no power, no chemicals, no salt required

-

No maintenance or drain needed

-

Retains calcium and magnesium; no sodium added

-

Reduces soap and detergent usage by up to 50%

-

Compact design fits in small spaces without large brine tanks

-

Saves energy by reducing scale buildup on heating surfaces

How It Works:

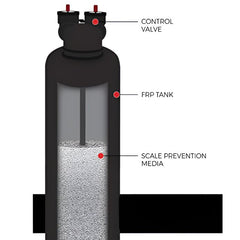

The TAC system uses porcelain beads with a crystal pattern etched on their surface. Calcium, magnesium, and bicarbonate ions form microscopic seed crystals on the beads instead of adhering to pipes or appliances. These crystals flow with the water, preventing scale and gradually dissolving existing buildup.

TAC is highly efficient, with up to 99.9% scale prevention, far outperforming magnetic or electrical methods.

Catalytic Carbon Filtration:

-

8"x48" Mineral Tank (Black or Blue)

-

Up-flow valve & adapter kit

-

Distribution tube

-

0.75 cu ft Catalytic Carbon media

Catalytic carbon is a highly effective absorbent, especially for chloramine removal. Its modified surface increases chemical absorption and catalytic activity. This up-flow system enhances contact time between water and media, improving filtration efficiency while eliminating the need for backwashing.

Kit Includes:

-

Scale-reduction media

-

Mineral tank with distributor assembly

-

In/Out up-flow valve

-

Bypass valve & adapters

-

Catalytic carbon filter (preloaded)

Up-flow Filtration Advantages:

Water enters from the top, flows through an upper basket, down the riser tube, and circulates through the filter media in a swirling motion. This design maximizes contact time, continuously fluffs the media, and improves overall performance without backwashing.

Returns Policy

You may return most new, unopened items within 30 days of delivery for a full refund. We'll also pay the return shipping costs if the return is a result of our error (you received an incorrect or defective item, etc.).

You should expect to receive your refund within four weeks of giving your package to the return shipper, however, in many cases you will receive a refund more quickly. This time period includes the transit time for us to receive your return from the shipper (5 to 10 business days), the time it takes us to process your return once we receive it (3 to 5 business days), and the time it takes your bank to process our refund request (5 to 10 business days).

If you need to return an item, simply login to your account, view the order using the "Complete Orders" link under the My Account menu and click the Return Item(s) button. We'll notify you via e-mail of your refund once we've received and processed the returned item.

Shipping

We can ship to virtually any address in the world. Note that there are restrictions on some products, and some products cannot be shipped to international destinations.

When you place an order, we will estimate shipping and delivery dates for you based on the availability of your items and the shipping options you choose. Depending on the shipping provider you choose, shipping date estimates may appear on the shipping quotes page.

Please also note that the shipping rates for many items we sell are weight-based. The weight of any such item can be found on its detail page. To reflect the policies of the shipping companies we use, all weights will be rounded up to the next full pound.

Related Products

Recently Viewed Products

- Choosing a selection results in a full page refresh.